NSC100 Controls Platform

NSC100 Nyle Kiln Control

Nyle has taken over 40 years of experience in the industry and created a control system that is transforming how operators interact with their equipment. We set out with two goals in mind; increase productivity and make the control easy to use.

Configurations Available

- 2 EMC Wafer Holders Moisture Probes Per Kit

- 8 Moisture Probes

- Automatic recording during a cycle

- Automatic control using EMC in the dry kiln chamber.

- Works with schedule control in standard package for step-by-step changes

Features

- 4 Additional Temp Probes Per Kit

- Automatic recording during a cycle

- Control set-points and climate during heat treating cycle

- Automatically turn off the equipment when heat treating has been completed.

- Works with Firewood, Pallets, and more!

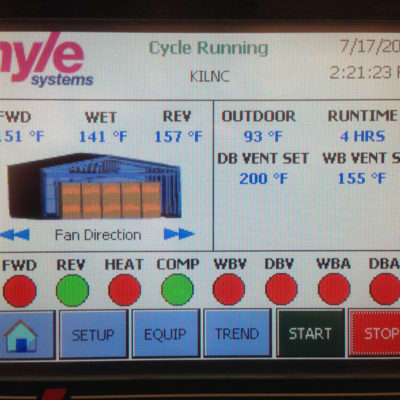

Color Touch Screen Interface

- 4″ or 7″ color touch screen for operator interface

- Built-in remote access

- Schedule Controls

- Data Logging and Trending

- Multiple built-in standard processing modes

Web-Based Control

The NSC100 advanced control offers state-of-the-art web server control. Kiln operators can use the built-in web server to monitor all kiln conditions on any device that is connected to the local area network. Connections are made easy with standard Cat5 wiring connections at each control. The web server can also be accessed via the web on cell phones, tablets, or home computers.

No Computer Required!

The NSC100 controller doesn’t require a computer for data logging or control! We are doing away with this point of failure and concern. The NSC100 data logs are stored entirely within the PLC. Any device connected to the same local area network can access the data files and send them to a printer. Now, if your computer dies, you can still dry your lumber without having to call in the geek squad!

When you are buying a Nyle Control, you are not only buying the equipment but also the support.

Contact a Nyle Representative for more details.