Hardwood Kilns

- Complete line of Steam, Dehumidification, and Indirect Fired Gas kilns.

- Corrosion-resistant aluminum, specially coated coils, and many other features for extra-long life.

- A modular construction system means fewer manufactured parts and shorter lead times without sacrificing the quality of workmanship.

- Both forklifts loaded and track style kilns.

- Installation services and turnkey packages are available for all sizes.

Conventional Indirect Gas Fired Kilns

Gas has become a low-cost alternative to heat your kiln, especially in areas with high electricity rates. The price of natural gas and even LP has dropped significantly, and it is expected to stay this way for a long time. This is why we have developed a range of indirect gas-fired kilns.

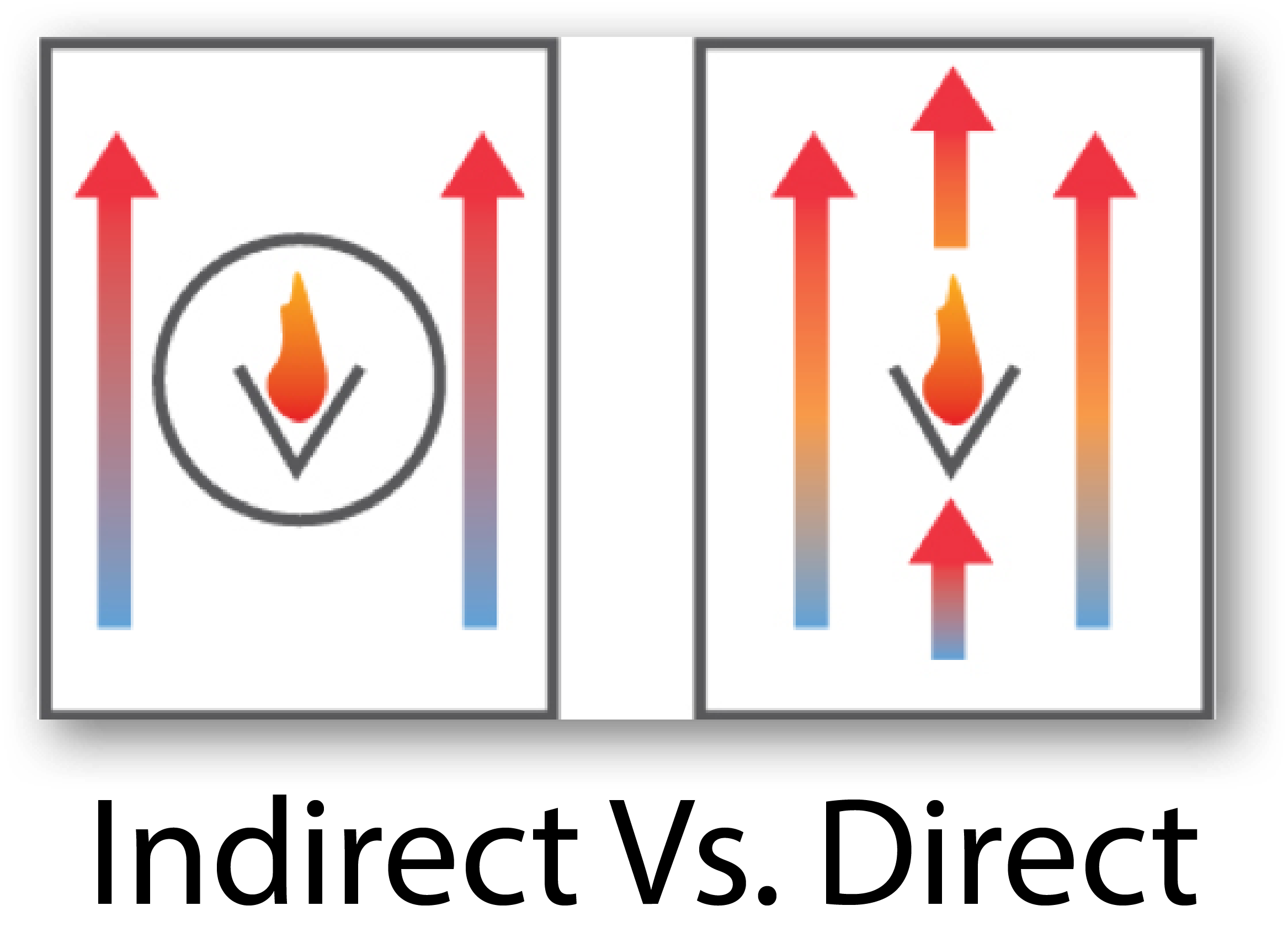

These kilns have a much better safety record than direct gas-fired kilns and allow for better quality control. With a direct gas-fired kiln, outside air is constantly being introduced into the kiln chamber, making it difficult to control the drying process properly.

Indirect systems don’t rely on a screen that corrodes over time to act as a filter to catch any flying debris from passing through the fire and igniting the kiln.

- Load sizes scalable to any size kiln.

- Up to 1.6MMBTUH per burner module

- Combine multiple modules for redundancy and capacity

- Easy to clean and maintain

- Long-lasting stainless and aluminum components

Dehumidification Kilns

Nyle is best known for its innovative dehumidification dry kiln systems. Nyle built and patented the first DH systems that allowed kilns to operate at the same temperatures as conventional steam and gas kilns.

Nyle is best known for its innovative dehumidification dry kiln systems. Nyle built and patented the first DH systems that allowed kilns to operate at the same temperatures as conventional steam and gas kilns.

A single Nyle dehumidification kiln drying unit can pull up to 20,000 pounds of water each day in a dry kiln. You can combine multiple units in a kiln to increase the capacity even further. Dehumidification drying means drying your boards for only pennies per square foot.

Dehumidification kilns are the most energy-efficient and economical drying method for most applications.

- Load ranges from 300BF to 300,000BF

- Standalone systems for custom built kilns or turnkey packages

- Same drying speeds as conventional gas and steam kilns

- Drying results with more precise temperature and RH controls means better color

- Fewer defects when drying

- Less risk to damage an entire load of lumber when drying

- Hybrid systems available to utilize both DH and Gas

Steam & Hot Water Coil Kilns

Nyle’s engineered steam and hot water coils are essential to properly maintaining temperature in a kiln. Nyle has worked exclusively with a quality coil provider to develop coils that last and are made explicitly for the lumber drying industry.

- Load ranges from 6,000BF to 16,000BF

- Operates between 80-180F

- Softwood Operation Costs – Propane: 65-70 Gallons/1000 BF, Electric Costs: 225 KWH/1000 BF

- Hardwood Operation Costs – Propane: 60-65 Gallons/1000 BF, Electric Costs: 250 KWH/1000 BF

Whether you are looking for a complete turn-key dry kiln system or specific components, Nyle will provide you with the best supplies on the market. Installation services are available for any size kiln that we sell.

We even have an online kiln store to buy specific components for upgrading, customization, or general replacement.

At Nyle, we don’t just want to sell you a kiln and call it a day. We want to develop relationships with our customers and be your kiln supplier for years to come.