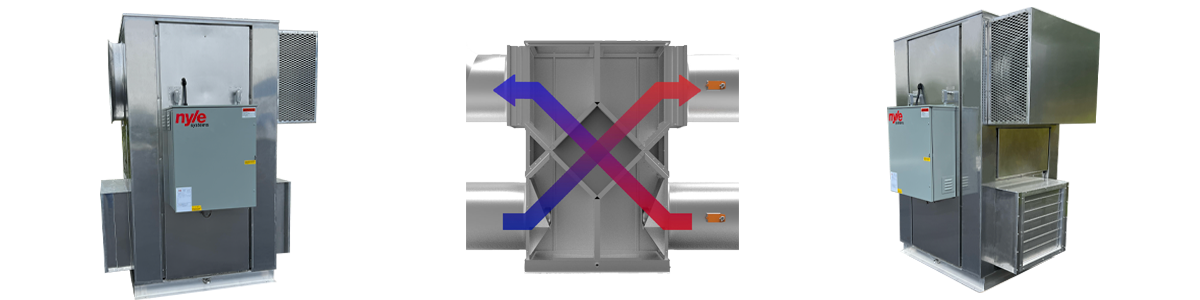

Heat Recovery Vent

Nyle’s focus has always been to support all Kiln owners and improve efficiency and productivity in lumber drying.

Nyle’s focus has always been to support all Kiln owners and improve efficiency and productivity in lumber drying.

Heat loss through venting is one of the most notable downfalls of a conventional kiln. With venting necessary to remove the excess moisture, you are stuck with considerable energy expenditure. This heat expenditure can significantly decrease your efficiency, increase your energy costs, and decrease degrade.

Our dynamic heat exchangers help recover energy lost during the drying process by transferring a large portion of the outgoing vented air’s energy to the incoming air. This process utilizes energy that would otherwise be wasted, minimizing the need for “reheating” and reducing overall fuel consumption by a minimum of 15%.

Product Comparison

| Unit | HRV 5000 | |

| Venting Capacity | 5,000 CFM | |

| Estimated Energy Savings | Up to 70% of lost heat from venting | |

| "Winter" Capacity (55º, 70% RH ambient) | 305,502 BTU/hr | |

| "Summer" Capacity (95º, 47% RH ambient) | 116,568 BTU/hr | |

| Intake/Exhaust Fan HP (at 1,800 RPM) | 6 HP total with VFD | |

| Static Pressure | 2" (at 5,000 CFM) | |

| Power Requirements | 480V three phase, 30A | |

| Venting BF Capacity (slow drying hardwoods) | 60 MBF | |

| Venting BF Capacity (mid-grade hardwoods) | 40 MBF | |

| Venting BF Capacity (fast drying hardwoods) | 20 MBF |